The Heat is On!

This crazy weather continues this year, and the Heat is setting record temperatures across North America. Last week we discussed how the heat was impacting your trucks, today we will look at the impact to your drivers.

What are you doing to protect your employees from Heat Stroke and exhaustion?

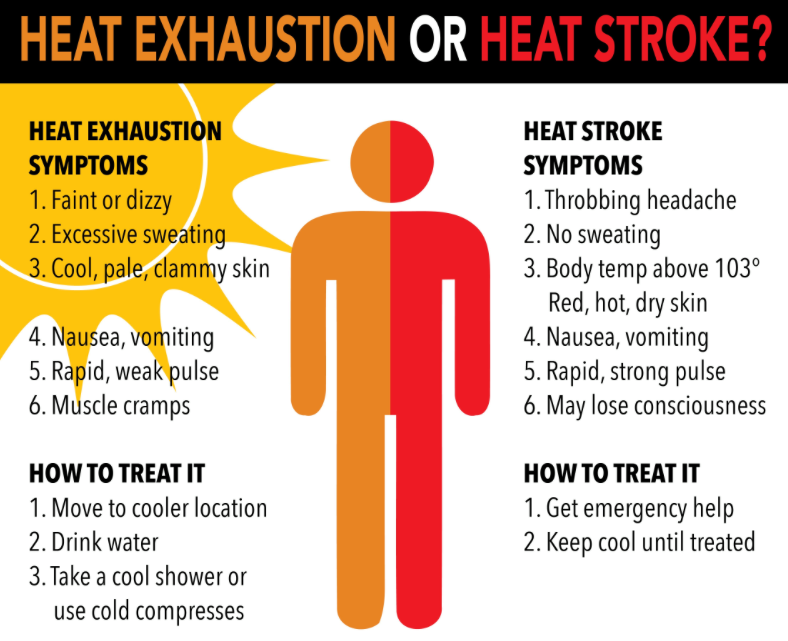

These conditions are created when our body is unable to regulate our heat production at a safe level. First, we need to make all our employees aware of the signs and symptoms for these conditions:

- Fatigue, weakness, fainting

- Nausea and vomiting

- Headache

- Dizziness

- Muscle cramps

- Irritability

- Sweating (absence or presence)

- Paleness

These conditions can be further escalated by the physical condition of your employees. Employees at a greater risk for heat exhaustion and heat stroke are those with: Heart disease, Skin diseases, Extensive burns, Endocrine disorders (hyperthyroidism, diabetes, etc.), High blood pressure, Overweight, Depression, Insomnia and Fever. Over the counter drugs can also contribute to a greater risk for these conditions.

ALL HEAT-RELATED ILLNESSES ARE PREVENTABLE!

What can you do to prevent them?

- Use Common Sense!

- Limit your exposure to direct sunlight as much as possible.

- Drink more fluids (non-alcoholic); do not drink fluids that contain caffeine or large amounts of sugar. Sport drinks are good as they replace electrolytes and salt in your body. Avoid extremely cold fluids as these can cause stomach cramps. Drink often throughout the day 4-6 ounces at a time. WATER IS GOOD!

- Wear lightweight, light-colored, loose-fitting clothing that does not create a safety hazard for your work environment. If outdoors, wear a hat to reduce direct exposure to the sun.

- Make sure your employees are wearing sunglasses that provide UV protection and are impact resistant

- Avoid hot foods and heavy meals. They add heat to your body.

- Drivers who are on routes should pack a cooler with water for the day. Also, keep an umbrella in the truck if you are operating in extreme conditions, (desolate, desert, etc.), this will allow you to move to an area with breeze and still be protected from the sun.

- If exposure to the sun is inevitable, apply generous amounts of sunscreen with a high SPF rating to exposed skin.

- Make sure your truck is in excellent condition. A good pre-trip inspection is crucial in extreme heat conditions to prevent breakdowns, otherwise you may find yourself and your unit on the side of the road exposed to the extreme heat.

Brake Safety Week Is Aug. 21-27

The Commercial Vehicle Safety Alliance (CVSA) has announced Aug. 21-27 as the dates for this year’s Brake Safety Week. Brake Safety Week is an annual commercial motor vehicle brake-safety inspection, enforcement and education initiative conducted by law enforcement jurisdictions in Canada, Mexico, and the U.S. During Brake Safety Week, inspectors will conduct their usual North American Standard Level I and V Inspections and capture and report brake-related data to CVSA. The results will be released in the fall.

Brake-related violations comprise the largest percentage of all out-of-service vehicle violations cited during roadside inspections, and according to last year’s three-day International Roadcheck data, brake systems and brake adjustment violations accounted for 38.9% of all vehicle out-of-service violations, the most of any category of vehicle violations. To address this, CVSA’s Brake Safety Week seeks to:

- Identify and remove commercial motor vehicles with critical vehicle inspection violation items identified in the North American Standard Out-of-Service Criteria from roadways.

- Conduct inspections and identify and acknowledge commercial motor vehicles that do not have critical vehicle inspection violations by affixing those vehicles with a CVSA decal.

- Encourage proactive vehicle maintenance in advance of the week.

- Highlight the hard work and commitment to safety by inspectors, drivers and motor carriers.

- Remind drivers and motor carriers about the importance of proper brake maintenance and vehicle pre-trip and post-trip inspections.

- Provide an opportunity for outreach and educational brake-safety efforts by inspectors.

During the brake portion of a vehicle inspection, inspectors will look for missing, non-functioning, loose, contaminated or cracked parts on the brake system, and non-manufactured holes (such as rust holes and holes created by rubbing or friction) and broken springs in the spring brake housing section of the parking brake. They will listen for audible air leaks around brake components and lines and ensure the air system maintains air pressure between 90-100 psi (620-690 kPa). Inspectors will also check for S-cam flip-over and measure pushrod travel. They will check that slack adjusters are the same length (from center of S-cam to center of clevis pin) and the air chambers on each axle are the same size. They will also inspect required brake-system warning devices, such as ABS malfunction lamp(s) and low air-pressure warning devices. In addition, inspectors will ensure the breakaway system is operable on the trailer, and inspect the tractor protection system, including the bleed-back system on the trailer.

In addition to reporting total inspections and brake-related out-of-service violations, inspectors will also capture and provide data on brake hose/tubing chafing violations – the focus area for this year’s Brake Safety Week.

“Poorly maintained brake systems can reduce the braking capacity and stopping distance of large trucks and motorcoaches, which poses a serious risk to driver and public safety,” said CVSA President Capt. John Broers with the South Dakota Highway Patrol. “In those split-second emergency situations, the proper functionality of the brake systems on large commercial motor vehicles is crucial.”